California

Well-known member

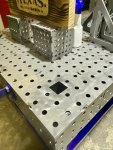

Following on from Lefty's thread where he decided to go ahead and buy a $20 welding table, let's see what others are using. There may be some inspirations here for new weldors just getting started.

I welded together four scrap mystery objects into a 1 x 4 ft welding table with an old tractor wheel for the base. To reduce fire hazard this is often taken outdoors so it has to be portable.

And just for fun to critique, here's the tractor wheel! I can't imagine what the prior owner did to cause this mess. Both front wheels looked like this - worse, with the welds all rusty and uneven - when I bought the tractor. I ran them without breaking anything for 15 years before finally replacing this one with an unblemished wheel. When I need to get a flat fixed I'll install my other replacement wheel. This tractor is semi-retired to backhoe use only, so the wheels don't see much stress now.

Comment - this software shows pictures strangely. Click a thumbnail to see it full size, then you need to click the box in lower right to see the wheel in the first photo. I tried uploading a smaller photo, same thing.

I welded together four scrap mystery objects into a 1 x 4 ft welding table with an old tractor wheel for the base. To reduce fire hazard this is often taken outdoors so it has to be portable.

And just for fun to critique, here's the tractor wheel! I can't imagine what the prior owner did to cause this mess. Both front wheels looked like this - worse, with the welds all rusty and uneven - when I bought the tractor. I ran them without breaking anything for 15 years before finally replacing this one with an unblemished wheel. When I need to get a flat fixed I'll install my other replacement wheel. This tractor is semi-retired to backhoe use only, so the wheels don't see much stress now.

Comment - this software shows pictures strangely. Click a thumbnail to see it full size, then you need to click the box in lower right to see the wheel in the first photo. I tried uploading a smaller photo, same thing.

Last edited:

![IMG_0056[1].JPG](/data/attachments/1/1416-72ccec3557fb32ebbc241b8053dfda23.jpg)

![IMG_0057[1].JPG](/data/attachments/1/1417-1466f14d586b9256299e3c5cbef4585e.jpg)