bplayer405

Well-known member

- Messages

- 211

- Good Post Points

- 55

Got all my ducks in a row; got the welder I've been after for years, spool gun, 100% argon - 2 small tanks, spools of wire, ss brushes, scrap material, ... finally nothing in my way. It was time to stop watching videos about everyone else welding aluminum and do it myself.

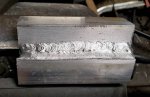

It took a bit find and to get use to the sound and the feel; it is quite different than welding steel. First weld was actually a weld, tall and ropey, but a continuous bead. A little more heat, better. Kept playing around for about half an hour and yes, I can do it too.

I definitely need practice. I'll definitely put in the time on all the joints I'll need to weld and get them as solid as I can. I have a opportunity to get a new-to-me Polar Kraft jon that'll need a floor conversion from a V to flat and decks framed and built. I get to that project I'll definitely post pics.

First time welding aluminum! Welds 1 through 4 then best and some joints...

View attachment 974View attachment 975View attachment 976View attachment 977

It took a bit find and to get use to the sound and the feel; it is quite different than welding steel. First weld was actually a weld, tall and ropey, but a continuous bead. A little more heat, better. Kept playing around for about half an hour and yes, I can do it too.

I definitely need practice. I'll definitely put in the time on all the joints I'll need to weld and get them as solid as I can. I have a opportunity to get a new-to-me Polar Kraft jon that'll need a floor conversion from a V to flat and decks framed and built. I get to that project I'll definitely post pics.

First time welding aluminum! Welds 1 through 4 then best and some joints...

View attachment 974View attachment 975View attachment 976View attachment 977