JWeir

Member

So I have an old project backhoe I bought for not much more than the price of scrap a couple years ago. I knew the floor was crap and patched, but it worked. I decided to tear it down, removed the zip screw patches and fix it better. I started with this.....and wondered if I should stop there.

I started cutting and grinding removing the rusted mess and was finally ready to make 1/4" plywood templates.

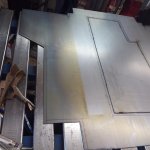

I got a couple sheets of 12 gauge, cut the rear panel first. I salvaged the rear radiused edge and welded that to the bottom as well as some 3/4 x 3/4 angle for the sides and some 1 1/2" 1/8" flat for the lip of the removable access panel (access to hydraulics, rear end, etc.).

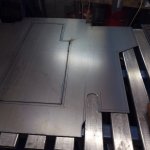

I cut the front panel and still have to finish the build up on the bottom of it, then I'll paint and finish prepping the machine for the install.

This is an ongoing project (the machine is at my camp 2 hours away) but I'd figure I'd post some progress pictures. I templated that parts there and am doing the panel work in my shop.

I started cutting and grinding removing the rusted mess and was finally ready to make 1/4" plywood templates.

I got a couple sheets of 12 gauge, cut the rear panel first. I salvaged the rear radiused edge and welded that to the bottom as well as some 3/4 x 3/4 angle for the sides and some 1 1/2" 1/8" flat for the lip of the removable access panel (access to hydraulics, rear end, etc.).

I cut the front panel and still have to finish the build up on the bottom of it, then I'll paint and finish prepping the machine for the install.

This is an ongoing project (the machine is at my camp 2 hours away) but I'd figure I'd post some progress pictures. I templated that parts there and am doing the panel work in my shop.